level 3 hard body impact test|ABUSE RESISTANT AND IMPACT : purchase Hard Body Minimum ft.-lb. Level 1 = 50 ft.-lb. Level 2 = 100 ft.-lb. Level 3 = 150 ft.-lb. Impact damage into the stud cavity caused by localized blows from hard objects, such as the corner . Since 1945 Parker Autoclave Engineers has designed and built premium quality valves, fittings and tubing. Parker Autoclave's high-pressure check valves are capable of operating to 60,000 .

{plog:ftitle_list}

Sterilization. Most medical and surgical devices used in healthcare facilities are made of materials that are heat stable and therefore undergo heat, primarily steam, sterilization.

ASTM C1629 has four test methods to quantify a level of abuse/impact resistance. Each test has a classification level (1-3), with 3 being the best. XP Hi-Abuse and XP Hi-Impact Gypsum Board were subjected to the four test .Impact-resistant gypsum panels are recommended for applications where both surface abuse and impact damage are concerns. Both abuse-resistant and impact-resistant gypsum panels meet .

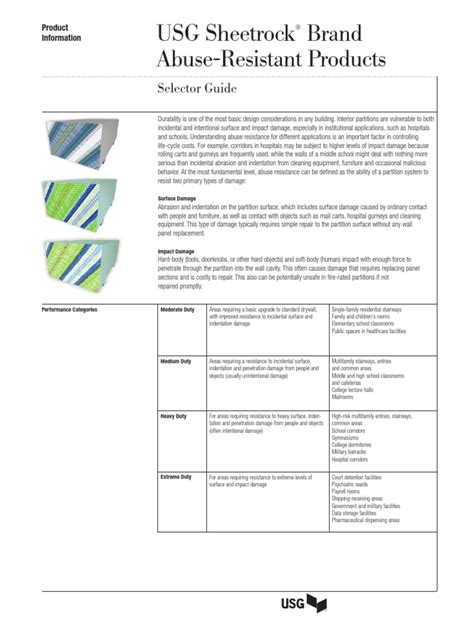

USG Sheetrock® Brand Abuse

Hard Body Minimum ft.-lb. Level 1 = 50 ft.-lb. Level 2 = 100 ft.-lb. Level 3 = 150 ft.-lb. Impact damage into the stud cavity caused by localized blows from hard objects, such as the corner . ASTM C1629, Standard Classification for Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement Panels, includes four test methods to quantify the level of abuse and impact .The main ASTM standard for abuse classification is ASTM C1629 which specifies the levels of performance. Annex A1 describes test methods for testing impact-resistant sheetrock and .For these and similar reasons the International Building Code requires interior exit stairways in high rise buildings be constructed using materials that meet or exceed Hard Body Impact .

1: The “Hard Body Impact Test” procedure is the most severe impact test and measures resistance to penetration of a wall panel when impacted by a rigid body. Failure is achieved .

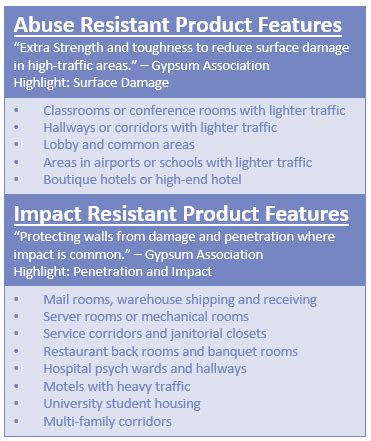

M-Bloc® IR Type X interior gypsum panels were designed and tested to not only provide exceptional resistance to mold and moisture, but superior resistance to impact penetration, abrasion, abuse and indention when compared to .“Impact-resistant” plasterboard can be defined as products that achieve very high levels of resistance to soft and hard body impact and surface indentation. Under the testing methods .ASTM C1629 has four test methods to quantify a level of abuse/impact resistance. Each test has a classification level (1-3), with 3 being the best. XP Hi-Abuse and XP Hi-Impact Gypsum Board were subjected to the four test methods: Surface abrasion, indentation, soft .USG testing demonstrates that when painted with one coat of primer and two coats of latex paint, the abrasion resistance increases to Level 3. Building design presents countless challenges, and USG can help you address key performance issues with our comprehensive portfolio of abuse- and impact-resistant solutions.

Impact-resistant gypsum panels are recommended for applications where both surface abuse and impact damage are concerns. Both abuse-resistant and impact-resistant gypsum panels meet the requirements of ASTM C1629/1629M and comply with the fire resistant requirements for Type X gypsum panels.Hard Body Minimum ft.-lb. Level 1 = 50 ft.-lb. Level 2 = 100 ft.-lb. Level 3 = 150 ft.-lb. Impact damage into the stud cavity caused by localized blows from hard objects, such as the corner of a wheeled cart or doorknob. Repair requires replacing the damaged wallboard.

ASTM C1629, Standard Classification for Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement Panels, includes four test methods to quantify the level of abuse and impact resistance. Each test method classifies the product as a Level I, Level II or Level III.The main ASTM standard for abuse classification is ASTM C1629 which specifies the levels of performance. Annex A1 describes test methods for testing impact-resistant sheetrock and other products for Hard Body Impact Resistance.For these and similar reasons the International Building Code requires interior exit stairways in high rise buildings be constructed using materials that meet or exceed Hard Body Impact Classification Level 3 (explained in detail later).

1: The “Hard Body Impact Test” procedure is the most severe impact test and measures resistance to penetration of a wall panel when impacted by a rigid body. Failure is achieved when the impacting head penetrates through the test panel surface.M-Bloc® IR Type X interior gypsum panels were designed and tested to not only provide exceptional resistance to mold and moisture, but superior resistance to impact penetration, abrasion, abuse and indention when compared to traditional wallboard.“Impact-resistant” plasterboard can be defined as products that achieve very high levels of resistance to soft and hard body impact and surface indentation. Under the testing methods established by ASTM C1629, these products have been proven to deliver exceptional results in the key performance areas.ASTM C1629 has four test methods to quantify a level of abuse/impact resistance. Each test has a classification level (1-3), with 3 being the best. XP Hi-Abuse and XP Hi-Impact Gypsum Board were subjected to the four test methods: Surface abrasion, indentation, soft .

USG testing demonstrates that when painted with one coat of primer and two coats of latex paint, the abrasion resistance increases to Level 3. Building design presents countless challenges, and USG can help you address key performance issues with our comprehensive portfolio of abuse- and impact-resistant solutions.Impact-resistant gypsum panels are recommended for applications where both surface abuse and impact damage are concerns. Both abuse-resistant and impact-resistant gypsum panels meet the requirements of ASTM C1629/1629M and comply with the fire resistant requirements for Type X gypsum panels.Hard Body Minimum ft.-lb. Level 1 = 50 ft.-lb. Level 2 = 100 ft.-lb. Level 3 = 150 ft.-lb. Impact damage into the stud cavity caused by localized blows from hard objects, such as the corner of a wheeled cart or doorknob. Repair requires replacing the damaged wallboard. ASTM C1629, Standard Classification for Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement Panels, includes four test methods to quantify the level of abuse and impact resistance. Each test method classifies the product as a Level I, Level II or Level III.

The main ASTM standard for abuse classification is ASTM C1629 which specifies the levels of performance. Annex A1 describes test methods for testing impact-resistant sheetrock and other products for Hard Body Impact Resistance.

For these and similar reasons the International Building Code requires interior exit stairways in high rise buildings be constructed using materials that meet or exceed Hard Body Impact Classification Level 3 (explained in detail later).1: The “Hard Body Impact Test” procedure is the most severe impact test and measures resistance to penetration of a wall panel when impacted by a rigid body. Failure is achieved when the impacting head penetrates through the test panel surface.

M-Bloc® IR Type X interior gypsum panels were designed and tested to not only provide exceptional resistance to mold and moisture, but superior resistance to impact penetration, abrasion, abuse and indention when compared to traditional wallboard.

The Ins

leak down test is good but hard start

The Bottom Line About Specifying Abuse or Impact

All-metal sealing and working temperatures from 0° to 600°F (-18° to 315°C), along with a variety of different material options make this connection one of the most versatile ever.

level 3 hard body impact test|ABUSE RESISTANT AND IMPACT